(J=W*s ;julios igual vatios por segundo)

1 eV = 1,620 10^-19 J

1 J = 6,1728 10^18 eV

1 julio o joule (J) es igual a 6.241509⋅1018 electron-volts (eV) *sacado de internet.

Sobre electro-imanes.

Sabiendo que los iones de protio (isótopo de hidrógeno) y otros iones en el magnetismo o dimensión magnética, generan la energía de la electricidad circulando por el campo magnético.(Teoria del Todo)

Se puede explicar el funcionamiento por ejemplo de los electro-imanes.

En los electro-imanes con núcleo (metal), este núcleo multiplica el campo magnético generado por la bobina al pasar los iones por el (el núcleo de metal): pues alinea el campo magnético de los átomos del metal, (a parte de generar calor por la desintegración de los iones) .

El efecto es como apilar imanes.

Sabiendo esto:

Un electro imán debería ser capaz de absorber iones y generar calor al chocar algunos iones con los átomos del metal del núcleo.

La bobina no debería calentarse en principio pues el campo magnético pasaría por el núcleo, debería generar energía; no de la" corriente" sino de los iones absorbidos no sería fusión exactamente. Todos los electro-imanes se calientan y es por esto habría que ver que les pasa si los expones a diferentes dosis de radiación si pueden proteger de esta como la tierra lo hace con su campo magnético del viento solar.

Energía generada electro-imán.

Fundir metal por inducción.

(Pese a que no tiene núcleo de hierro que aumente el efecto magnético de la bobina un horno de fundición de metales me parece interesante pues tiene una bobina que genera un campo magnético.)

De la misma manera que funcionan las cocinas eléctricas; por inducción también hay maquinas que funden metal, y revisando maquinaria industrial realicé unos cálculos.

"Como se mencionó anteriormente, el consumo de energía estándar para la fundición de chatarra ligera de aluminio requiere 600 a 625 kWh/tonelada (considere un promedio de 612,5 kWh). Eso significa que una tonelada de chatarra ligera de aluminio requiere de 600 a 625 kWh".

Cálculo:

1 W (vatio) = 1 J (julio) * s (segundo)

1 kW⋅h = 3,6 MJ

625 kWh → 2.250 MJ (mega julios) para fundir 1000 Kg

2.250.000 J → 1 Kg

Vamos a calcular que energía tiene el aluminio fundido de 660 ºC respecto al aluminio solido de 0ºC y usaremos ese valor para orientarnos.

“Energía para fundir un kilo 900 julio/kilogramo”

“Calor específico: El calor específico de una sustancia se define como la cantidad de julios (o calorías) necesaria para cambiar la temperatura de exactamente 1 g de una sustancia por exactamente 1 C. “

“La capacidad calorífica es la cantidad de calor absorbida (emitido) todo el cuerpo en proceso de calentamiento (enfriamiento) por 1 Kelvin. “

“En termodinámica, la entalpía de fusión de una sustancia, también conocida como calor (latente) de fusión, es el cambio en su entalpía resultante de proporcionar energía, típicamente calor, a una cantidad específica de la sustancia para cambiar su estado de un sólido a un líquido, a presión constante. Por ejemplo, al derretir 1 kg de hielo (a 0 °C bajo un amplio rango de presiones), se absorben 333,55 kJ de energía sin cambio de temperatura. El calor de solidificación (cuando una sustancia cambia de líquido a sólido) es igual y opuesto.”

datos (1):

Masa

atómica aluminio: 26,9815386 u gramos por mol (sale de la tabla periódica)

Calor especifico del aluminio: 0.9 J/g K.

Punto de fusión Aluminio: 933,47 K (660 °C)

Entalpía de fusión aluminio: 10,71 kJ/mol

datos(2):

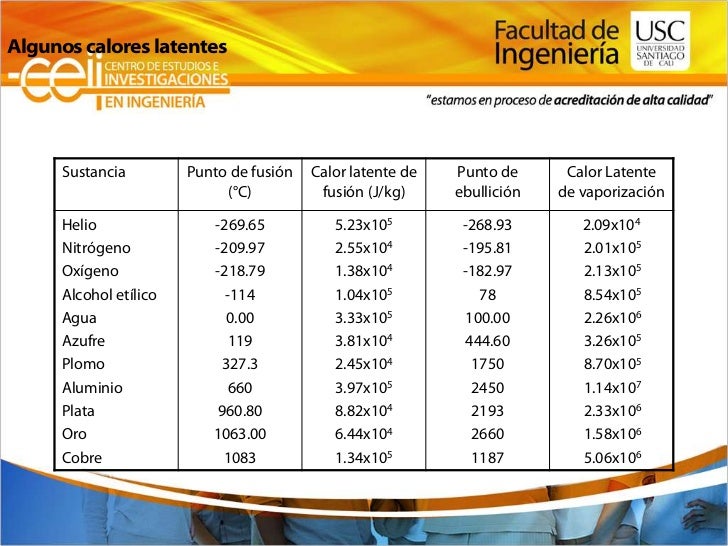

Sustancia |

T fusión ºC |

Lf ·103 (J/kg) |

T ebullición ºC |

Lv ·103 (J/kg) |

|---|---|---|---|---|

Hielo (agua) |

0 |

334 |

100 |

2260 |

Alcohol etílico |

-114 |

105 |

78.3 |

846 |

Acetona |

-94.3 |

96 |

56.2 |

524 |

Benceno |

5.5 |

127 |

80.2 |

396 |

Aluminio |

658.7 |

322-394 |

2300 |

9220 |

Estaño |

231.9 |

59 |

2270 |

3020 |

Hierro |

1530 |

293 |

3050 |

6300 |

Cobre |

1083 |

214 |

2360 |

5410 |

Mercurio |

-38.9 |

11.73 |

356.7 |

285 |

Plomo |

327.3 |

22.5 |

1750 |

880 |

Potasio |

64 |

60.8 |

760 |

2080 |

Sodio |

98 |

113 |

883 |

4220 |

Fuente: Koshkin N. I., Shirkévich M. G.. Manual de Física elemental, Edt. Mir (1975) págs. 74-75.

Total:

Total:

Earlier we calculated 396.93 kJ to go from

solid to liquid.

594 kJ+ 396.93 kJ

990.93

kJ

Using data(2)

0.9 J/g K * 658.7 K =0.9 kJ/kg

K * 658.7 K= 594 kJ to raise the temperature by 658.7 K to one

kilo.

Total:

592.83 kJ

592.83 kJ

+322 kJ

914.83 kJ

Energy of a kilo of aluminum

already melted at 660°C compared to solid aluminum at 0°C

914.83

kJ is needed for a kilo of aluminum to melt from 0ºC to 660ºC at

least. For that is the energy it possesses at that temperature.

The

machinery has needed

2250 kJ

So it does not

generate energy in the form of heat (it was a scrap melting

machine).

Or so it seems.

It happens that

aluminum is not ferromagnetic and does not multiply the effect of the

electromagnet, and does not affect because the protons or ions have

been attracted by electricity even so the heat has been generated by

the disintegration of these as we have seen before.

Ferromagnetic

materials would be:

Iron (Fe)

Cobalt

(Co)

Nickel (Ni)

Steel

alloys

etc.

With ferromagnetic materials,

electro-magnets can be created by the effect I described above.

"An

object is considered ferromagnetic if a magnet sticks to it."

"Is

aluminum ferromagnetic?

Aluminum is one of the

paramagnetic metals, which means that magnets only weakly attract it.

So weakly that you might think that they have no influence on

aluminum. However, the video presented to you here demonstrates that

magnets do have an effect on aluminum."

The information I have:

Energy consumption to

melt 1 ton metals in one hour:

For melting cast iron

it takes 550-575 kWh/ton.

For SG Iron melting it requires

550-600 kWh/ton.

For Stainless Steel/Steel melting 600-650

kWh/ton is required

For Aluminum light scrap melting

600-625 kWh/ton is required.

500-575 kWh/ton is required

for melting Aluminum chopped scrap.

For steel melting 625

kWh/ton is required.

Weight per cubic meter metals:

Steel 7850 kg/m³

?

Aluminum 2700 kg/m³ 26.9815

Bronze with tin

8900 kg/m³ ?

Bronze with lead 8700 kg/m³ ?

Copper

8960 kg/m³ 63.5460

Iron 7300 kg/m³ 55.8450

Brass

8560 kg/m³ ?

Aluminio |

2700 kg/m³ |

26.9815 g/mol |

600-625 kWh/ton |

Cobre |

8960 kg/m³ |

63.5460 |

? |

Hierro |

7300 kg/m³ |

55.8450 |

550-575 kWh/ton |

Acero |

7850 kg/m³ |

? |

625 kWh/ton |

Aluminio (chatarra troceada) |

? |

? |

500-575 kWh/ton |

Aluminum with 2700 kg/m³ is the lightest but requires 600-625 kWh/tonne.

Iron with a density of 7300 kg/m³ per cubic meter is 2.7 times denser than aluminum.

For the same weight:

For the melting of light Aluminum scrap 600-625 kWh/ton is required.

500-575 kWh/ton for the melting of aluminum scrap

Cast iron melting requires 550-575 kWh/tonne

Aluminum 0.0269815 Kg/mol

Iron 0.0558450 Kg/mol

0.0000269815 Ton/mol 37,062.4316 mole of Aluminum per ton of Aluminum.

0.0000558450 Ton/mol 17,906.7060 mole of Iron per ton of Iron.

There are 2.0697 times as many moles of aluminum as of iron in a ton.

And the mole of iron is 2.0697 times heavier than the mole of aluminum.

The energy of melting cast iron for the machine 575 kWh

and I calculate the joules:

575 kWh

575 000 W * 3600 s

2,070,000,000,000 J/s (W)

2.250 kJ → 1 Kg Aluminium.

83.390,4711 kJ * 37,0624 mol → 0,4444 J/mol

2,070 kJ → 1 Kg Iron.

37.066,88142 kJ * 17,9067 mol → 0,4830 J/mol

Despite the difference in density and weight per cubic meter the performance of the machines is similar in terms of heat in joules to melt one mole.

I continue with the checks:

Stationary Acutrak®

Power Density

150 Kilowatts per Ton

Power Requirements

167 KVA, 460/480 Hz, 50/60 Hz

https://www.inductotherm.com/products/acutrak-direct-electric-heat-deh-system/

for 167 KVA

approx 0.9 power factor

150300 W (150 kW per Ton)

for one ton 1 T or 1000Kg

(150 kWh/T)=

in one hour 60 minutes * 60 seconds

150300*(360)

54.108.000 J

I will calculate the results in electron volts as well:

"The electron volt is a unit of energy that represents the energy variation experienced by an electron when moving from a point of potential Va to a point of potential Vb when the difference Vba = Vb-Va = 1 V, that is, when the potential difference of the electric field is 1 volt."

3.3771558755e+26 eV

914,830,000 J minimum to melt 1000 kg of aluminum from 0 to full melting.

5.7099 10^27 eV

i.e:

But with initial data (not catalog data):

625 Kilowatt hours would consume to melt 1000 kilos of aluminum

2.250.000.000.000 J to melt 1000 kg

1.4043 10^28 eV

Something strange is going on here...

I look at industrial machinery below.

https://www.induction-furnace.com/products/aluminum-melting-furnace/

Aluminum Melting Furnace

Miro maquinaria industrial a continuación.

https://www.induction-furnace.com/products/aluminum-melting-furnace/

Aluminum Melting Furnace

Model |

Power Control Cabinet |

Furnace Body |

Associated Transformer(KVA) |

|||||||

Power |

Voltage |

MF Voltage |

Cabinet Size(mm) |

Frequency |

Weight |

Furnace body Size(mm) |

Induction Coil Inner Diameter |

Weight |

||

0.1T |

80kw |

3×380v |

750v |

1000×800×1700 |

2500 |

0.5T |

Φ730 |

Φ500 |

0.7T |

125 |

0.25T |

180kw |

3×380v |

750v |

1300×850×2000 |

2000 |

0.8T |

Φ1100 |

Φ580 |

1T |

250 |

0.35T |

200kw |

3×380v |

750v |

1300×850×2000 |

1500 |

0.8T |

Φ1100 |

Φ700 |

1.2T |

400 |

0.5T |

400kw |

3×380v |

1500v |

1300×850×2000 |

1500 |

1T |

Φ1250 |

Φ760 |

1.5T |

500 |

0.75T |

600kw |

3×380v |

1500v |

1300×850×2000 |

1000 |

1T |

Φ1350 |

Φ840 |

1.6T |

630 |

1T |

700kw |

3×660v |

2400v |

1300×850×2000 |

800 |

1.2T |

Φ1400 |

Φ960 |

1.8T |

900 |

1.5T |

8000kw |

3×660v |

2500v |

1300×850×2000 |

600 |

1.2T |

Φ1700 |

Φ1150 |

2.5T |

1250 |

2T |

1000kw |

3×660v |

2500v |

1300×850×2000 |

600 |

1.6T |

Φ1700 |

Φ1350 |

3T |

1600 |

3T |

1500KW |

3×950v |

3200v |

2400×1000×2000 |

500 |

1.6T |

Steel shell |

Φ1450 |

12T |

2500 |

5T |

2000KW |

6×950v |

3400V |

2400×1000×2000 |

500 |

2.5T |

Steel shell |

Φ1800 |

19T |

3300 |

Product Introduction

The heating furnace is mainly used for heating of metal materials before forging, extrusion, hot rolling, shearing, and heat treatment of metal materials, such as quenching, tempering, tempering and the like. Heating temperature is between 200-1200 degrees.

Pre-forging heating: applied to gear, ring gear, bearing, shackle, rigging.

Online heating: Pipe anti-corrosion coating, long steel rod heating, steel (wire) tube online quenching and tempering.

Local heating: U-bolt bending, thermal assembly of the drum,Steel pipe elbow etc.

Product Features

The induction coil is insulated by two insulation treatment, high temperature insulating paint and fiberglass ribbon winding.

The top of the furnace body is designed with sliding cover, which is convenient for maintenance and inspection.

Equipment installation and operation is simple.

Equipment covers a small area

Stable and reliable heating temperature

Power consumption280kwh/ton

Technical Parameter

Technical Parameter

Model |

Power Input(3-Phase 4-Wire 50/60Hz) |

Power Output |

Capacity(Kg/h) |

|||||||

Power |

Voltage |

Current |

DC Current |

DC Voltage |

MF Voltage |

MF Frequency |

Steel |

Copper |

Aluminum |

|

KGPS-50 |

50KW |

380V |

80A |

100A |

500V |

750V |

1-8KHZ |

125 |

282 |

234 |

KGPS-50 |

50KW |

380V |

80A |

100A |

500V |

750V |

1-8KHZ |

125 |

282 |

234 |

KGPS-750 |

750KW |

380V 660V |

1200A 680A |

1500A 850A |

500V 880V |

750V 1300V |

0.2-6KHZ |

1875 |

4230 |

3510 |

Working Temperature: Steel 1250℃, Copper 900℃,Aluminum 500℃ |

||||||||||

Power Consumption: Steel 350-550KWH/T, Copper 150-300KWH/T, Aluminum 180-400KWH/T |

||||||||||

I will calculate the maximum consumption: 400kWh per ton.

400kWh

per 1000 Kg

400000Wh per 1000 Kg

1,440,000,000

W(J) in one hour.

1,440,000,000 joules(W) per

kilo.

Electron-volt

8.9877 10^24 eV per kilo.

potencia de entrada: 50KW 380V 80A

potencia de salida: 100A 500V (DC)

Capacidad: 234Kg/h

We calculate:

50000 W

18,000,000 J in one hour

(234 Kg)

76,923,0769 J one kilo

76.923.076,923

J 1000 Kg (1 T)

76.923.076,923 J/(1 T) / 18.000.000 J in

one hour (234 Kg)

4.2735 hours to melt 1000 Kg (1

T)

4.8011610333 10^26 ( one joule or joule (J) is equal to

6.241509⋅1018 electron-volts (eV))

50000 W * 4.2735

h

213.675 kWh/T

that system would need

213,675 kWh/h to melt 1000 kg (1T) in one hour then

is

within the range: Aluminum "180-400KWH/T" and what they

suggest "Power consumption 280 kwh/ton".

compare

with previous system: (Acutrak® Melting Systems aluminum melting

machine from www.inductotherm.com (150 Kilowatts per Ton per Hour)).

167 kVA now at 380

=253.73 A

=96.417,4

W

34,710,264 J an hour (almost double)

and

if they had the same efficiency it would have melted:

34,710,264 / 76,923.0769 J one kilo.

451.2334

kg in one hour

2.21614 h to melt 1000 Kg(1 T)

or

76.923.082,3782 J to melt 1000 Kg (1 T)

54.108.000

J to melt 1000 Kg (this is the data that gives 150 kW/T) so the first

one was more efficient but they are very similar in performance.

I

recalculate the minimum energy to melt aluminum with another method

and get out of doubt.

Formula used:

"Thermal energy = Specific gravity of

material*Volume of molten metal*(Specific heat capacity*(Base metal

melting temperature-Ambient temperature)+Latent heat of fusion).

Q = (SG*V*(c*(Tm-ta)+ΔHf)*4.2)/(1-R)

This

formula uses 8 Variables.

Variables utilizadas:

Thermal energy - (Measured in Joule) - Thermal energy is the total

amount of heat required.

Material specific gravity

- Material specific gravity is a dimensionless unit defined as the

ratio of the density of the material to the density of water at a

specific temperature.

Molten Metal Volume -

(Measured in Cubic Meter) - Molten metal volume is defined as the

volume of material removed during the LBM process.

Specific

heat capacity - (Measured in joule/kilogram/K) - Specific heat

capacity is the heat required to raise the temperature of the unit

mass of a given substance by a given amount.

Base

metal melting temperature - (Measured in Kelvin) - The melting

temperature of the base metal is the temperature at which its phase

changes from liquid to solid.

Ambient temperature - (Measured in

Kelvin) - The ambient temperature is the temperature of the

surroundings.

Latent heat of fusion - (Measured in

joule/meter³) - The latent heat of fusion or enthalpy of

solidification is the heat released during solidification. Enter the

magnitude only. It is taken negative by default."

2.7 Specific gravity of the material [SG] times density water with

respect to water

1 Volume of molten metal [V] cubic

meter

8.96 Specific heat capacity [c] kilojoule per

kilogram

933.47 K Melting temperature of the base metal

[Tm] kelvin

0°C + 273.15

= 273.15 K Ambient

temperature [ta] kelvin

3.97*10^5 (J per kilo) *2700 (kg

per meter³ ) = 1,071,900,000 J Latent heat of fusion [ΔHf] joule

meter3

0.9 Reflectivity of the material [R]"

I have adjusted the formula for the data I have:

Q =

(SG*V*c*(Tm-ta))+ΔHf

(2,700 kg × 1 m³ ×

8.96 kJ/kg × (933.47 ºK - 273.15 ºK)) + 1,071,900 kJ

(2,700

kg × 5,916.4672 kJ) + 1,071,900 kJ

1.597.446,44 kJ +

1.071.900 kJ

2.669.346,44 kJ for 2700 kg

988,6468

kJ for 1 kg

988,646.829 kJ for 1000 kg

6.1706

10^27 eV for 1000 kg

I compare results for melting 1000 kg of

aluminum by induction.

Calculated values for reference use:

914.830 kJ energy as

minimum to melt 1000 kg of aluminum.(from periodic table data and

constants).

5.7099 10^27 eV minimum energy to melt 1000 kg

of aluminum (from periodic table data and constants).

988.646,829

kJ for 1000 kg of aluminum (minimum according to aluminum values and

physics formulas).

6.1706 10^27 eV for 1000 kg of aluminum

(minimum according to aluminum values and physics formulas).

Values

calculated from manufacturer's data and available on the

internet:

2,250,000 kJ per 1000 kg uses the machinery that

I looked at the beginning of the article; as they say 625 kW 1h 1000

kg (as expected by generic data).

1.4043 10^28 eV per 1000

kg uses the machinery I looked at at the beginning of the article;

according to 625 kW 1h 1000 kg (according to expectations by

data).

1,440,000 kJ per 1000 kg (based on the industrial

furnaces for aluminum smelting www.induction-furnace.com that I

mentioned before (maximum energy consumption)).

8.9877

10^27 eV per 1000 kg (based on the industrial furnaces for aluminum

smelting www.induction-furnace.com mentioned above (maximum energy

consumption)).

76,923.0769 kJ per 1000 kg (based on the

industrial furnaces for aluminum smelting www.induction-furnace.com

mentioned above (for the KGPS-50 model)).

4.8011 10^26 eV

per 1000 kg (based on the industrial furnaces for aluminum smelting

www.induction-furnace.com that I have mentioned above (for the

KGPS-50 model)).

54,108,000 kJ 1000 kg (Acutrak® Melting

Systems aluminum melting machine from www.inductotherm.com (150

Kilowatts per Ton per Hour)).

3.3771 10^26 eV 1000 kg

(Acutrak® Melting Systems aluminum melting machine from

www.inductotherm.com (150 Kilowatts per Ton per

Hour)).

Conclusion

Commercial induction machines that

melt aluminum do so with less energy than expected.

No hay comentarios:

Publicar un comentario